This fender was one of my first composite (fiberglass) projects. The tire in these pictures is a 10" x 7".

This is for the GET, GY6 will be different, but the concept should still aply.

First the materials need. I was lucky enough to live near a Fiberlay store so I picked up everything I needed from there.

- Fiberglass resin (epoxy will also work) just make sure you get resin that will air dry.

- Polyvinyl Alcohol (PVA) this is the release.

- Fiberglass fabric – I got both Biaxial and twill weave.

- Mixing and measuring cups.

- Paint brushes.

- And some modeling clay

- Some thin 1/2" foam (note: resin will melt some types of foam)

- Duct tape

I started by wrapping the tire with the foam. The foam should give a good gap between the fender and tire when all is done. I used the duct tape to hold and shape the foam to the tire. This is also the stage used for figuring out how I wanted to mount the fender.

I purposely left a flare on the bake of the fender, but once done I never liked the flare.

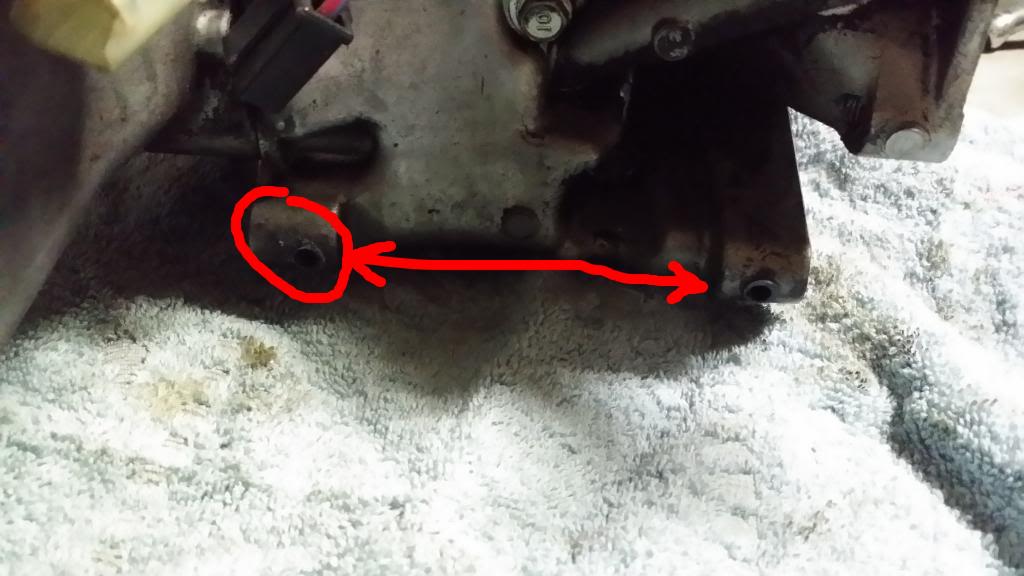

The red arrows point to the lower mounting points. I drilled out the casting marks and then tapped the holes. For the third mounting point on top I made a bracket to use the stock location off the radiator (you can see it in later pictures).

Here you can see how I used the clay to build out the mounting locations.

Also masked off or covered the rest of the rim to keep unwanted resin from getting on it.

The dipstick was going to be in the way so I cut out some of the foam to make room for it. At this point I painted the whole thing (all the duct tape) with the PVA.

Time to lay down the glass. I used 3 layers, the biaxial is sandwiched between the twill. I just let it drape over the tire.

The fiberglass has been removed from the wheel and is now ready to be trimmed and sanded. This is the itchy step.

Rough trimming done and test fitting. You can see the bracket I made for the top mount.

More test fitting, and another shot of the top bracket. I made the top bracket out of plastic, I have plastic strap left over from the IceTubes (radiator overflow) that I was making at the time.

I haven’t trimmed the back as I wasn’t sure how I wanted to trim it.

Still need to clean up the cuts.

All painted and ready for some rain.

I eventually had to add a mount to the back as the fender would bounce around a lot. Here you can see the mount coming off the exhaust.